Mould Oscillation Assembly

Mould Oscillation Assembly Specification

- Surface Finish

- Corrosion Resistant

- Noise Level

- 75 dB

- Drive Type

- Electric Motor Driven

- Capacity

- Heavy Duty/Industrial

- Usage & Applications

- Continuous Casting Machines in Steel Plants

- Shape

- Rectangular Base, Cylindrical Shafts

- Lubricating System

- Centralized Grease Lubrication

- Motor Power

- 3 HP

- Diameter

- Up to 120 mm (Shaft)

- Size

- Customizable

- Product Type

- Mould Oscillation Assembly

- Material

- High Grade Steel

- Technology

- Precision Machining

- Power Source

- Electric

- Power

- 5 kW

- Voltage

- 380 V

- Pressure

- Hydraulic System Supported

- Surface Treatment

- Polished and Coated

- Dimension (L*W*H)

- 1200 mm x 500 mm x 800 mm

- Weight

- 950 kg

- Color

- Silver/Grey

Mould Oscillation Assembly Trade Information

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- corrugated /wooden boxes

- Main Export Market(s)

- Australia, North America, Eastern Europe, Africa, Western Europe, Central America, Middle East, South America, Asia

- Main Domestic Market

- All India

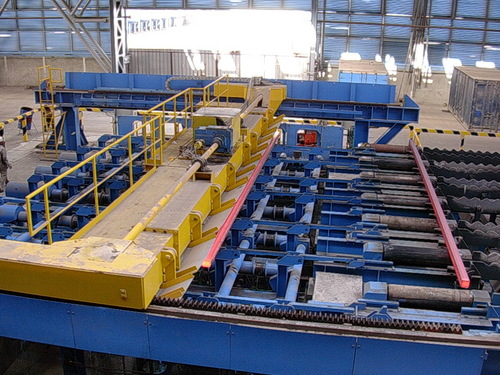

About Mould Oscillation Assembly

With the help of our technically sound professionals, we are able to manufacture, supply and export Mould Oscillation Assembly. Used for continuous casting machines, this assembly is fabricated using advanced components. Each part of the assembly is precisely engineered by skilled workers to ensure their dimensional accuracy. We have employed a team of quality experts who thoroughly analyze the assembly for its sturdiness and optimum functioning. Made available in varied specifications, the Mould Oscillation Assembly finds great usage in different industrial segments.

Features:

- Sturdy construction

- Precisely engineered

- Non-corrosive

- Easy to install

Precision Engineering for Demanding Applications

Designed using advanced precision machining technology, the Mould Oscillation Assembly delivers exceptional accuracy and stability crucial for continuous casting processes. High-grade steel construction, paired with a corrosion-resistant finish, ensures outstanding longevity even in harsh environments. The robust rectangular base and cylindrical shafts provide optimal rigidity and support, accommodating heavy-duty industrial requirements.

Advanced Electric and Hydraulic Integration

Driven by a 5 kW electric motor and supported by a hydraulic system, this assembly achieves consistent oscillation with minimal vibration. The inclusion of a centralized grease lubrication system reduces maintenance needs and increases operational lifespan. Its quiet operation, even at high capacities, makes it an asset to steel plants focused on efficiency and workplace safety.

FAQs of Mould Oscillation Assembly:

Q: How does the Mould Oscillation Assembly enhance the continuous casting process in steel plants?

A: The assembly provides precise, steady oscillation to moulds during casting. This action promotes uniform solidification of molten steel, reduces surface defects, and improves slab quality overall, resulting in more efficient production and higher output standards.Q: What advantages does the corrosion-resistant, polished, and coated surface offer?

A: The specialized surface treatment shields the assembly from rust and environmental degradation, thereby extending its lifecycle. It also reduces maintenance intervals and costs, ensuring reliable performance in demanding steel plant conditions.Q: When should the centralized grease lubrication system be checked or refilled?

A: Routine inspections should follow the manufacturers maintenance schedule, typically at set operational hour intervals. Regular monitoring guarantees optimal lubrication of moving parts, minimizing wear and unscheduled downtime.Q: Where is the ideal installation setting for this assembly?

A: This assembly is engineered for integration with continuous casting machines in steel plants. Its robust design and electric-driven power make it suitable for both new installations and retrofit projects requiring precision, reliability, and heavy-duty performance.Q: What is the process for customizing the assemblys size or shaft diameter?

A: Customization begins with a technical consultation to define plant requirements. The manufacturer then adapts dimensions, shaft diameter (up to 120 mm), and specifications to seamlessly fit existing or new casting lines, optimizing operational compatibility.Q: What are the main benefits of using an electric motor-driven, hydraulic-supported oscillation assembly?

A: Electric motor operation ensures consistent, controllable oscillation, while hydraulic support adds operational stability. This combination results in smooth, low-maintenance performance, improved casting quality, energy efficiency, and reduced noise (75 dB).

- Minimum Order Quantity

- depends Unit

- Main Domestic Market

- All India

- Main Export Market(s)

- Australia, North America, Eastern Europe, Africa, Western Europe, Central America, Middle East, South America, Asia

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Casting Machine Spare Parts Category

Rigid Dummy Bar Storage

Minimum Order Quantity : depends Unit

Usage & Applications : Continuous Casting Machines in Steel Plants

Product Type : Other, Rigid Dummy Bar Storage

Color : Industrial Grey

Technology : Other, Precision Engineering

Lubricating System : Centralized Automatic Lubrication

Casting Platform

Minimum Order Quantity : depends Unit

Usage & Applications : Supporting casting operations in foundries and metal processing plants

Product Type : Other, Casting Platform

Color : Grey

Technology : Other, Welding and Fabrication

Lubricating System : Manual Lubrication

Discharge Roller Table

Minimum Order Quantity : depends

Usage & Applications : Rolling Mills, Steel Plants, Metal Processing Units, Conveyor Lines

Product Type : Other, Discharge Roller Table

Color : Industrial Grey / Blue / Customized

Technology : Other, Hot Rolled

Lubricating System : Manual/Automatic Centralized

Continuous Casting Machine Pusher Assembly

Minimum Order Quantity : depends Unit

Usage & Applications : Continuous Casting Machinery in Steel and Metal Industries

Product Type : Other, Continuous Casting Machine Pusher Assembly

Color : Metallic Grey / Customized

Technology : Other, Advanced Fabrication and Machining

Lubricating System : Centralized Lubrication Provided