Cast Spray Pipes

Cast Spray Pipes Specification

- Feature

- Corrosion resistant, even spray distribution, robust cast design

- Rating

- High performance, manufacturer quality approved

- Condition

- New

- Type

- Spray Pipe

- Usage

- Industrial, agricultural, and machinery cooling systems

- Size

- 3/4 inch to 6 inch (custom sizes available)

- Dimensions

- Varies as per size selection

- Weight

- Depends on size; approximately 0.8 to 6 kg

- Application

- Cooling, water spray, dust control, and irrigation systems

- Fuel Type

- Not required

- Capacity

- Handles high flow rates, customized as per requirement

Cast Spray Pipes Trade Information

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- standard ,corrugated box ,wooden box

- Main Export Market(s)

- Australia, North America, Eastern Europe, South America, Africa, Western Europe, Central America, Middle East, Asia

- Main Domestic Market

- All India

About Cast Spray Pipes

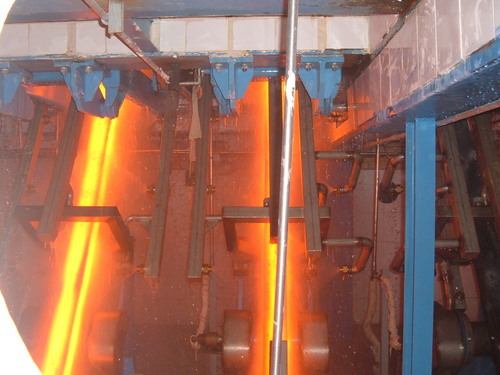

Leveraging on our experienced acquired since 2007, we are engaged in manufacturing, supplying and exporting Cast Spray Pipes. Our professionals use high grade stainless steel along with latest machines to obtain the end product in compliance with the international quality norms. Mainly used for cooling purpose, these pipes find great usage in steel industry. To meet the variegated demands of our patrons, we offer these Cast Spray Pipes in different dimensions.

Features:

- Accurate dimensions

- High tensile strength

- Resistance to corrosion

- Lightweight

Other Details:

Cast Spray Pipes

| Function | Uniform and intensive cooling of the hot strand leaving the mould |

| Location | Attached to the mould support casing, directly underneath of mould |

| Construction | Section size related spray tubes. Set of 4 individual spray pipes connected to a manifold. Individual plug-in type spray pipes for each face of billet. Perfectly aligned spraying system following the casting arc. Uniform water distribution. Easy exchange of spray pipes in case of section change or damage (e.g. break-outs). Spray system is oscillating with the mould. |

| Type of nozzles | Full cone brass spray nozzles |

| Position of spray pipes | To edges and faces of billets |

Reliable Solution for Industrial and Agricultural Spraying Needs

Cast Spray Pipes deliver dependable performance across a variety of industrial and agricultural sectors. With high-capacity flow rates and the ability to meet custom dimensional requirements, these spray pipes are ideally suited for use in cooling systems, water spraying, dust suppression, and irrigation. The sturdy construction ensures longevity, even in challenging operating environments.

Key Features: Durability and Customization

Manufactured with robust cast materials, these spray pipes offer excellent corrosion resistance and even spray distribution. Their strength allows them to withstand demanding industrial conditions. Options for size customization enable tailored solutions, ensuring compatibility with your specific applicationwhether for machinery cooling or agricultural irrigation.

FAQs of Cast Spray Pipes:

Q: How are cast spray pipes typically used in industrial and agricultural settings?

A: Cast spray pipes are primarily used for cooling machinery, spraying water, dust control, and irrigation in both industrial and agricultural environments. Their design enables even spray distribution for efficient system performance.Q: What customization options are available for these spray pipes?

A: Pipes can be customized in terms of size, capacity, and specific application needs. Options range from 3/4 inch to 6 inch in diameter, with the capability to produce intermediate sizes according to customer requirements.Q: When should I consider using cast spray pipes over other types?

A: Choose cast spray pipes when you require a robust, corrosion-resistant solution that can manage high flow rates, demands reliability, and ensures even spray performanceespecially in cooling, irrigation, or dust suppression systems.Q: Where can I install cast spray pipes for optimal performance?

A: These pipes are ideal for installation in industrial machinery cooling systems, agricultural irrigation setups, water spraying lines, and dust control frameworks. They can be adapted to both indoor and outdoor environments depending on specific project requirements.Q: What is the process for ordering custom-sized cast spray pipes?

A: To order custom sizes, provide your desired dimensions and capacity requirements during the inquiry process. The manufacturer or supplier will work with you to design and deliver pipes tailored to your specifications.Q: How do cast spray pipes benefit my operation compared to standard piping?

A: They offer superior durability, reliable performance in high-demand applications, even spray distribution, and resistance to corrosion. This reduces maintenance, extends service life, and enhances the efficiency of your cooling, irrigation, or dust control systems.

- Minimum Order Quantity

- Depends on Product Ton

- Main Domestic Market

- All India

- Main Export Market(s)

- Australia, North America, Eastern Europe, South America, Africa, Western Europe, Central America, Middle East, Asia

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Continuous Casting Machine Category

Tundish Preheater

Minimum Order Quantity : depends Unit

Type : Industrial Preheater

Dimensions : As per customer/plant requirement

Size : Customized as per Tundish capacity

Application : Continuous casting process

Rating : Up to 2000 kW

Industrial Ladle Machine

Minimum Order Quantity : depends Unit

Type : Ladle Machine

Dimensions : Standard / Custom on demand

Size : Customizable as per requirements

Application : Steel Plants, Foundries, Casting Industries

Rating : Industrial Grade

Bar Pinch Roller Assembly

Minimum Order Quantity : depends Unit

Type : Bar Pinch Roller Assembly

Dimensions : As per drawing and requirement

Size : Customizable, as per requirement

Application : Rolling Mills, Metal Processing Plants

Rating : Heavy Duty Industrial

Ladle Turret

Minimum Order Quantity : depends Unit

Type : Industrial

Dimensions : As per project design

Size : Customizable as per requirement

Application : Ladle handling in steelmaking operations

Rating : Heavy Duty