Ladle Turret

Ladle Turret Specification

- Rating

- Heavy Duty

- Feature

- Robust construction, High load bearing, Precision rotation

- Condition

- New

- Type

- Industrial

- Usage

- Steel Plant, Converter Shop, Foundry

- Power

- Electric, Hydraulic

- Voltage

- 415 V

- Size

- Customizable as per requirement

- Dimensions

- As per project design

- Application

- Ladle handling in steelmaking operations

- Capacity

- Up to 300 tons

- Finish

- Painted/Coated for corrosion resistance

- Safety Features

- Limit switches, Overload protection, Emergency stop

- Material

- Alloy Steel, Mild Steel Structure

- After Sales Service

- Available

- Speed of Rotation

- Adjustable depending on operation need

- Rotation Angle

- 360 Degrees Continuous

- Control System

- PLC/Remote/Manual Control Options

- Mounting

- Floor mounted

Ladle Turret Trade Information

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- corrugated /wooden boxes

- Main Export Market(s)

- North America, Eastern Europe, Middle East, Africa, Western Europe, Central America, Australia, South America, Asia

- Main Domestic Market

- All India

About Ladle Turret

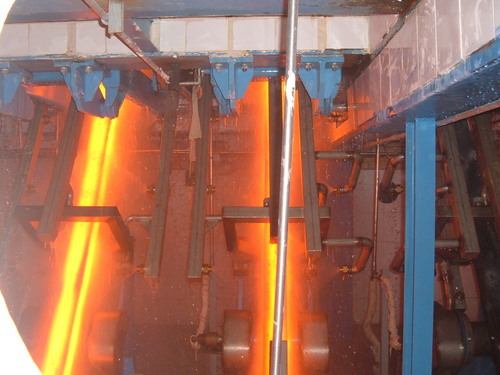

Backed by a team of competent professionals, we are indulged in manufacturing, supplying and exporting Butterfly Type Ladle Turret. Offered turrets are designed in such a way that make these easy to operate without the need of much training. To make sure compliance of the offered machine with the quality standards mentioned in the industry norms, it is subjected to rigorous checks on several predefined parameters. Butterfly Type Ladle Turret is offered in varied specifications to meet the requirements of clients.

Features:

- Low maintenance

- High tensile strength

- Non-corrosive

- Trouble-free performance

Unmatched Performance for Steel Handling

Engineered to withstand rigorous industrial conditions, the Ladle Turret delivers superior load-bearing capacity and seamless rotation for high-demand steelmaking applications. Its precision engineering and high-quality materials make it integral to modern steel plants and foundries.

Comprehensive Safety Measures

The Ladle Turret is fitted with advanced safety features, including emergency stops, limit switches, and overload protection. These safeguards ensure operator confidence, minimize risks, and maintain uninterrupted operationsideal for environments where safety is paramount.

Flexible Control and Customization

Operators enjoy a choice of PLC, remote, or manual controls, enabling seamless integration into any workflow. Custom dimensions and power options ensure compatibility with unique project requirements and variable site conditions.

FAQs of Ladle Turret:

Q: How does the Ladle Turret enhance safety during ladle handling operations?

A: The Ladle Turret incorporates safety features such as emergency stop buttons, limit switches, and overload protection devices. These measures reduce operational risk, provide quick intervention in emergencies, and ensure precise stopping points to avoid accidents.Q: What control options are available for operating the Ladle Turret?

A: This equipment supports PLC-based automation, remote control, and manual operation, allowing users to select the method that best fits operational needs. These versatile controls facilitate integration into existing systems and offer adaptability for efficient workflow.Q: When should the speed of rotation be adjusted?

A: Speed adjustments are recommended during different stages of ladle transfer, depending on the load and required positioning accuracy. Operators can modify the rotation speed to ensure both safety and efficiency while accommodating varied operational demands.Q: Where is the Ladle Turret typically installed?

A: The Ladle Turret is mainly floor-mounted within steel plants, converter shops, and foundries. Its installation location is determined by project requirements and the layout of the handling area to optimize workflow and accessibility.Q: What is the process for customizing a Ladle Turret for a specific application?

A: Customization begins with a thorough assessment of load capacity, operational dimensions, and control preferences. The manufacturer then designs and fabricates the turret to suit the customers unique project requirements, followed by painting or coating for corrosion resistance.Q: How does robust construction benefit steelmaking operations?

A: The heavy-duty design, using alloy or mild steel, provides high load-bearing strength and resilience to harsh industrial conditions. This robustness translates to reliable, long-term service with reduced maintenance downtime in demanding steel plant environments.Q: What after-sales support is offered with the Ladle Turret?

A: Comprehensive after-sales service is available, including installation, commissioning, training, maintenance, and troubleshooting. This support ensures optimal performance and maximizes uptime for steelmakers and foundries across India.

- Minimum Order Quantity

- depends Unit

- Main Domestic Market

- All India

- Main Export Market(s)

- North America, Eastern Europe, Middle East, Africa, Western Europe, Central America, Australia, South America, Asia

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Continuous Casting Machine Category

Tundish Preheater

Minimum Order Quantity : depends Unit

Type : Industrial Preheater

Size : Customized as per Tundish capacity

Application : Continuous casting process

Dimensions : As per customer/plant requirement

Condition : New

Industrial Torch Cutting Machine

Minimum Order Quantity : depends Unit

Type : Manual/Automatic Torch Cutting Machine

Size : Standard (custom options available)

Application : Metal Plate Cutting

Dimensions : Approximately 1200 mm x 800 mm x 950 mm

Condition : New

Cast Spray Pipes

Minimum Order Quantity : Depends on Product Ton

Type : Spray Pipe

Size : 3/4 inch to 6 inch (custom sizes available)

Application : Cooling, water spray, dust control, and irrigation systems

Dimensions : Varies as per size selection

Condition : New

Industrial Ladle Machine

Minimum Order Quantity : depends Unit

Type : Ladle Machine

Size : Customizable as per requirements

Application : Steel Plants, Foundries, Casting Industries

Dimensions : Standard / Custom on demand

Condition : New