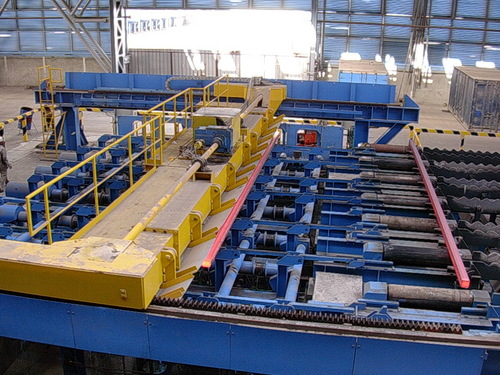

Casting Platform

Casting Platform Specification

- Surface Finish

- Smooth

- Size

- As per required

- Motor Power

- 3 HP

- Drive Type

- Electric Drive

- Usage & Applications

- Supporting casting operations in foundries and metal processing plants

- Shape

- Rectangular

- Lubricating System

- Manual Lubrication

- Noise Level

- Low

- Product Type

- Casting Platform

- Material

- Mild Steel

- Technology

- Welding and Fabrication

- Power Source

- Electric

- Power

- 3 kW

- Pressure

- Standard Atmospheric

- Surface Treatment

- Paint Coated

- Dimension (L*W*H)

- Customized

- Weight

- Up to 750 Kg

- Color

- Grey

Casting Platform Trade Information

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- corrugated /wooden boxes

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Africa, Western Europe, Central America, South America, Asia

- Main Domestic Market

- All India

About Casting Platform

Counted amongst well established organizations, we are engaged in manufacturing, supplying and exporting Casting Platform. With the help of these platforms, oscillation system and strand guide can be accessed with ease. Our expert engineers take utmost care while making these platforms so as to meet the exact demands of varied industrial applications. We offer this Casting Platform as per the specifications provided by clients in order to serve their needs in the most satisfactory manner.

Features:

-

Precisely engineered

-

Resistant to corrosion

-

Robust construction

Additional information:

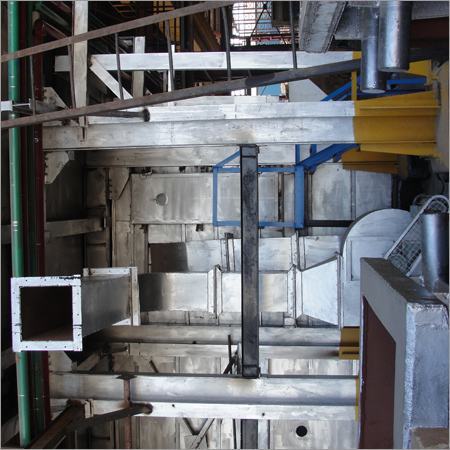

Construction prefabricated steel construction made up of columns and beams (main columns are of cast-in type).The structure is independently erected from buildings. This prevents vibrations from the cranes etc. being transmitted to the continuous casting process. Spacious casting platform Maintenance platforms for good access to oscillation system and strand guide. Stairways and The most important stairways and walkways have walkways a width of 1 m, the less frequented ones a width of 0,8 m.

Precision Engineering for Foundry Support

Our casting platform delivers exceptional stability and safety for casting processes in foundries and metalworking plants. Constructed from mild steel and fabricated through expert welding, this platform ensures both longevity and reliability in demanding industrial settings. Its tailored sizing and smooth, paint-coated finish enable optimal performance and visual appeal.

Customizable Design for Unique Operations

Every casting workflow is unique, and our platform can be built to your specific dimensions and requirements. With a maximum weight capacity of 750 kg and customizable length, width, and height, it adapts seamlessly within your facility, supporting both large and small scale operations.

FAQs of Casting Platform:

Q: How is the casting platform utilized in metal processing plants and foundries?

A: The casting platform supports and stabilizes casting molds, materials, and equipment during metalworking operations, facilitating precise, safe, and efficient casting processes in foundries and metal processing plants.Q: What materials and technology are used in constructing the platform?

A: The platform is manufactured from high-quality mild steel, employing advanced welding and fabrication techniques to ensure both strength and longevity under heavy industrial usage.Q: When should you consider using a customized casting platform?

A: Custom platforms are ideal when your processes require specific dimensions, load capacities, or unique layouts to accommodate specialized equipment or space constraints in your foundry or plant.Q: Where can this casting platform be installed and utilized?

A: It is designed for use in a range of industrial facilities, including foundries, smelting plants, and various metal processing environments throughout India and globally.Q: What is the process involved in maintaining the casting platform?

A: Basic maintenance involves periodic inspection of welds, paint coating, and surface finish, as well as manual lubrication of moving components to ensure smooth operation and a longer service life.Q: How does the platforms design benefit foundry operations?

A: Its smooth, paint-coated surface prevents material buildup, while the robust rectangular shape and low-noise, electric-driven operation enhance workflow efficiency and operator safety.Q: What are the advantages of choosing a platform with manual lubrication and low noise levels?

A: Manual lubrication simplifies routine maintenance, and low noise operation improves workplace comfort, fostering a safer and more pleasant environment for workers.

- Minimum Order Quantity

- depends Unit

- Main Domestic Market

- All India

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Africa, Western Europe, Central America, South America, Asia

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Casting Machine Spare Parts Category

Mould Cooling System

Minimum Order Quantity : Depends Unit

Size : Standard

Technology : Other, Advanced Heat Exchange

Noise Level : Low (<60 dB)

Shape : Rectangular

Usage & Applications : Plastic Mould Cooling, Injection Molding Machines

Continuous Casting Machine Pusher Assembly

Minimum Order Quantity : depends Unit

Size : Standard & Customized Sizes

Technology : Other, Advanced Fabrication and Machining

Noise Level : Low Noise Operation

Shape : Rectangular with Push Arm

Usage & Applications : Continuous Casting Machinery in Steel and Metal Industries

Duct Steam Exhauster

Minimum Order Quantity : depends

Size : Standard

Technology : Other, Centrifugal Exhaust

Noise Level : <70 dB

Shape : Rectangular Duct Design

Usage & Applications : Commercial Kitchens, Food Processing Plants, Industrial Exhaust

Discharge Roller Table

Minimum Order Quantity : depends

Size : Custom sizes available

Technology : Other, Hot Rolled

Noise Level : Below 70 dB

Shape : Rectangular base with cylindrical rollers

Usage & Applications : Rolling Mills, Steel Plants, Metal Processing Units, Conveyor Lines