Continuous Casting Machine Pusher Assembly

Continuous Casting Machine Pusher Assembly Specification

- Lubricating System

- Centralized Lubrication Provided

- Features

- High Efficiency, Rugged Construction, Easy Installation, Durable and Reliable

- Usage & Applications

- Continuous Casting Machinery in Steel and Metal Industries

- Motor Power

- 5 HP to 30 HP (Depending on Model)

- Shape

- Rectangular with Push Arm

- Size

- Standard & Customized Sizes

- Capacity

- Heavy Duty, Large Volume Operations

- Drive Type

- Mechanical/Hydraulic/Electric

- Noise Level

- Low Noise Operation

- Product Type

- Continuous Casting Machine Pusher Assembly

- Material

- High Grade Alloy Steel

- Technology

- Advanced Fabrication and Machining

- Power Source

- Hydraulic / Electric

- Power

- Customizable as per requirement

- Voltage

- 380V / 415V / 440V

- Pressure

- Up to 250 Bar (Hydraulic System)

- Dimension (L*W*H)

- As per machine requirement or customized

- Color

- Metallic Grey / Customized

Continuous Casting Machine Pusher Assembly Trade Information

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- corrugated /wooden boxes

- Main Export Market(s)

- Australia, Eastern Europe, Middle East, South America, Africa, Western Europe, Central America, Asia, North America

- Main Domestic Market

- All India

About Continuous Casting Machine Pusher Assembly

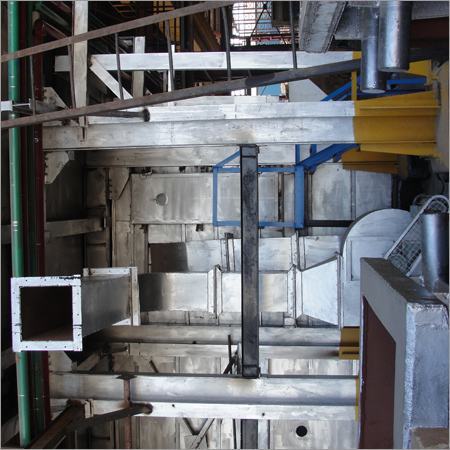

Continuous Casting Machine Pusher Assembly

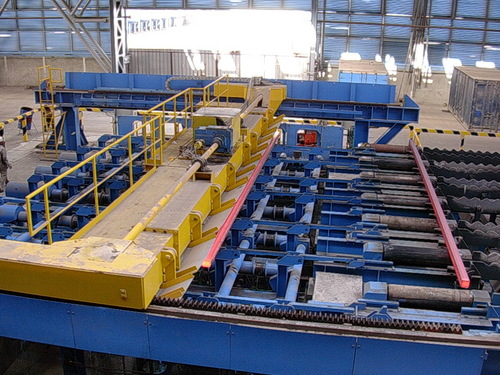

Continuous Casting Machine Pusher Assembly is comforted with arms which are Retractable lifting. The pusher assembly has a very tough and rigid construction and the parts of the machine eases the task of removing, lifting and also serves the exact positioning of billets onto the cooling bed. It is used to remove the billets from the lower level. Now one might wonder which lower area is being mentioned here so it is the bottom area of the cross transfer. Continuous Casting Machine Pusher Assembly is further efficient to lift and transport items towards the cooling bed.

| Function | To remove the billets from the lower level of the cross transfer area and to lift and transport them towards the cooling bed |

| Location | At right angles to the discharge roller tables in cross transfer area |

| Construction | Retractable lifting arms. Rigid construction. Smooth removing, lifting and exact positioning of billets onto the cooling bed. |

| Lifting actuation | Hydraulic cylinder and mechanically synchronized |

Engineered for Heavy-Duty Operations

The Continuous Casting Machine Pusher Assembly is crafted from high-grade alloy steel with advanced machining, ensuring rugged operation even under demanding industrial conditions. Its flexible power options and robust mechanical structure make it ideal for continuous duty in steel and metal casting facilities, effectively handling large volumes with minimal downtime.

Customized to Your Specifications

With fully customizable power capacities, dimensions, colors, and drive types, the pusher assembly can be tailored to precise manufacturing requirements. Whether standard or bespoke, every unit incorporates centralized lubrication and low-noise operation for optimal efficiency. This adaptability streamlines integration into new or existing casting machinery.

FAQs of Continuous Casting Machine Pusher Assembly:

Q: How does the Continuous Casting Machine Pusher Assembly benefit steel and metal industry operations?

A: This pusher assembly optimizes the material handling process in continuous casting machinery, enabling efficient, uninterrupted production cycles. Its high efficiency, heavy-duty capacity, and rugged construction are tailored for the rigorous demands of steel and metal industries, reducing operational downtime and maintenance needs.Q: What power and voltage options are available for this pusher assembly?

A: The assembly is available with both hydraulic and electric power options, supporting voltages of 380V, 415V, or 440V. Motor power ranges from 5 HP to 30 HP, and hydraulic systems can operate at pressures up to 250 Bar, ensuring compatibility with various industrial energy systems.Q: When should I choose a customized pusher assembly for my facility?

A: Customization is recommended when your facility has unique dimensional, power, or application needs that standard models cannot fulfill. The manufacturer offers tailored solutions, including custom sizes, power, and design features, to ensure seamless integration and optimal performance for your continuous casting operations.Q: Where can the Continuous Casting Machine Pusher Assembly be installed?

A: This assembly is designed for use in steel and metal industry facilities employing continuous casting machinery. It can be integrated into both new setups and upgrades across foundries, steel mills, and metal manufacturing plants.Q: What is the process for installing and commissioning the pusher assembly?

A: Installation involves mounting the assembly according to your machines specific dimensions, connecting the drive (mechanical, hydraulic, or electric), setting up the centralized lubrication system, and calibrating operational parameters. Professional support from the manufacturer or authorized service providers ensures correct setup and system reliability.Q: How does the centralized lubrication system improve operation?

A: A centralized lubrication system automatically supplies necessary lubrication to crucial moving parts, reducing friction, wear, and maintenance intervals. This feature enhances operational reliability and prolongs the lifespan of the assembly, even during continuous heavy-duty usage.Q: What makes this pusher assembly durable and reliable for industrial use?

A: Its construction from high-grade alloy steel, advanced fabrication, robust rectangular design, and customizable components collectively deliver durability. These features withstand heavy mechanical loads and harsh operational environments, ensuring long-term reliability and consistent productivity.

- Minimum Order Quantity

- depends Unit

- Main Domestic Market

- All India

- Main Export Market(s)

- Australia, Eastern Europe, Middle East, South America, Africa, Western Europe, Central America, Asia, North America

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Casting Machine Spare Parts Category

Mould Cooling System

Minimum Order Quantity : Depends Unit

Surface Finish : Smooth

Noise Level : Low (<60 dB)

Technology : Other, Advanced Heat Exchange

Size : Standard

Power Source : Other, Electric

Discharge Roller Table

Minimum Order Quantity : depends

Surface Finish : Smooth / Painted / Polished

Noise Level : Below 70 dB

Technology : Other, Hot Rolled

Size : Custom sizes available

Power Source : Other, Electric

Duct Steam Exhauster

Minimum Order Quantity : depends

Surface Finish : Polished

Noise Level : <70 dB

Technology : Other, Centrifugal Exhaust

Size : Standard

Power Source : Other, Electric

Casting Platform

Minimum Order Quantity : depends Unit

Surface Finish : Smooth

Noise Level : Low

Technology : Other, Welding and Fabrication

Size : As per required

Power Source : Other, Electric