Duct Steam Exhauster

Duct Steam Exhauster Specification

- Shape

- Rectangular Duct Design

- Capacity

- 850 m/h

- Motor Power

- 1 HP

- Usage & Applications

- Commercial Kitchens, Food Processing Plants, Industrial Exhaust

- Drive Type

- Belt Drive

- Size

- Standard

- Surface Finish

- Polished

- Noise Level

- <70 dB

- Diameter

- 250 mm (Inlet/Outlet Diameter)

- Product Type

- Duct Steam Exhauster

- Material

- Stainless Steel

- Technology

- Centrifugal Exhaust

- Power Source

- Electric

- Power

- 1 HP

- Pressure

- Medium

- Surface Treatment

- Powder Coated

- Dimension (L*W*H)

- 650 x 435 x 850 mm

- Weight

- 48 kg

- Color

- Silver

Duct Steam Exhauster Trade Information

- Payment Terms

- Cash Advance (CA), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- corrugated /wooden boxes

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- Main Domestic Market

- All India

About Duct Steam Exhauster

Leveraging on the experience of our highly qualified technicians, we are manufacturing, supplying and exporting Duct Steam Exhauster. All products are made at our sophisticated manufacturing unit, which is well equipped with all latest machinery required in the process. These are used for removing the steam produced in cooling chamber during the process of continuous casting. We offer Duct Steam Exhauster in different configurations to suit the specific needs of clients.

Features:

-

Compact design

-

Easy to install

-

Non-corrosive

-

High tensile strength

Additional information:

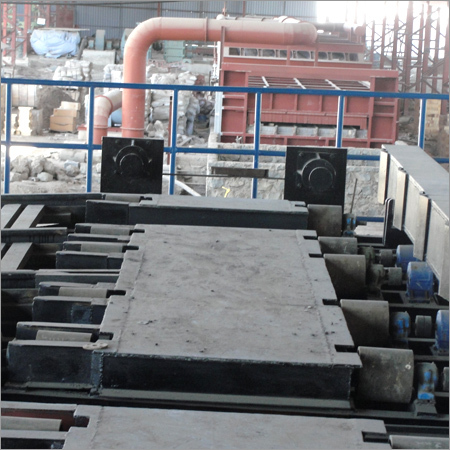

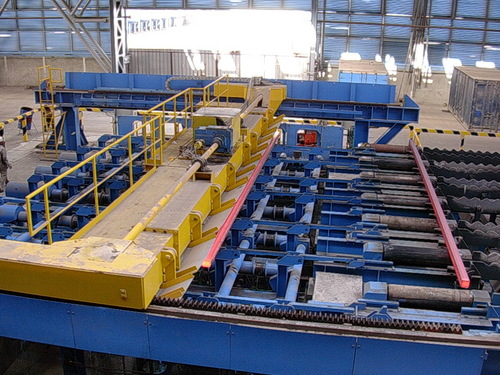

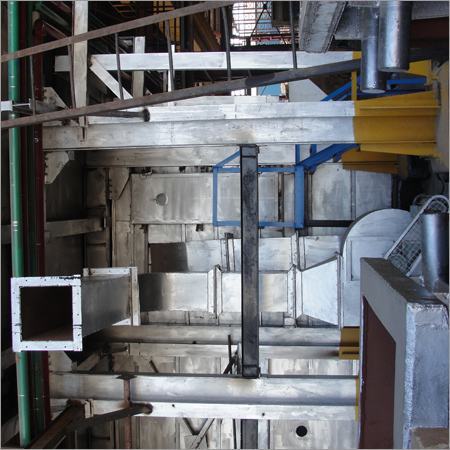

| Function | Extraction of steam generated in cooling chamber |

| Location | Located between walls of cooling chamber compartments and steel structure boundary of CCM |

| Construction | Galvanized steel sheet duct. Individual suction lines for each compartment resulting in optimized steam extraction from cooling chamber. |

High-Performance Extraction for Professional Environments

With its 1 HP motor and advanced centrifugal technology, the Duct Steam Exhauster delivers consistent, high-capacity extraction suitable for commercial kitchens, food processing facilities, and industrial operations. Its robust build and powder-coated finish ensure long-lasting use even in challenging environments. The design prioritizes safety, reliability, and energy efficiency.

Streamlined Installation and Versatile Application

Measuring 650 x 435 x 850 mm and weighing 48 kg, the exhauster is crafted for seamless integration into standard duct systems. The rectangular design with 250 mm diameter inlet/outlet accommodates a variety of layouts. Suitable for use by dealers, traders, exporters, and service providers, this unit meets diverse operational demands across India.

Reliable and Low-Maintenance Operation

Operating below 70 dB, the exhauster minimizes noise disruption while efficiently handling medium-pressure airflow. The belt drive system is engineered for durability and low maintenance, while the stainless steel construction resists corrosion and wear, simplifying upkeep and ensuring longtime reliability.

FAQs of Duct Steam Exhauster:

Q: How does the Duct Steam Exhauster contribute to improved air quality in industrial and kitchen settings?

A: By utilizing centrifugal exhaust technology and a high-capacity 1 HP motor, the Duct Steam Exhauster effectively removes steam, smoke, and airborne particulates, enhancing air quality and maintaining a safer, more comfortable environment in commercial kitchens and food processing plants.Q: What is the recommended process for installing the Duct Steam Exhauster in existing ductwork?

A: Installation involves aligning the units 250 mm inlet/outlet with corresponding duct links, securing it within the rectangular duct system, and powering the electric motor via a suitable electrical connection. Its compact dimensions and rectangular shape simplify integration in most standard setups.Q: When should this exhauster be maintained to ensure optimal performance?

A: Routine inspections and belt adjustments are suggested every 3-6 months, depending on usage intensity. Cleaning the stainless steel surfaces and ensuring there are no obstructions in the ducts or outlet can further prolong the units lifespan and efficiency.Q: Where is the Duct Steam Exhauster typically used, and what environments benefit most from its features?

A: This exhauster is ideal for commercial kitchens, food processing plants, and diverse industrial applications where effective air and steam removal are crucial. Its robust design and medium-pressure handling make it well-suited to demanding high-traffic environments.Q: What are the key benefits of using the Duct Steam Exhauster over conventional exhaust fans?

A: Key benefits include durable stainless steel construction, higher extraction capacity (850 m/h), efficient centrifugal operation, lower operational noise (<70 dB), and long service life with minimal upkeep, which translate into enhanced safety and productivity.Q: How can dealers, distributors, or service providers in India source and support this product?

A: Suppliers, wholesalers, and service providers can obtain the Duct Steam Exhauster directly from the manufacturer and authorized traders. Comprehensive after-sales support, installation guidance, and maintenance services are typically available to ensure smooth operation.

- Main Domestic Market

- All India

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Casting Machine Spare Parts Category

Billet Stopper

Minimum Order Quantity : depends Unit

Usage & Applications : Steel Plants, Continuous Casting Machines, Billet Handling Operations

Product Type : Other, Billet Stopper

Technology : Other, Forged and Machined

Color : Industrial Grey or Custom

Drive Type : Hydraulic Drive

Casting Platform

Minimum Order Quantity : depends Unit

Usage & Applications : Supporting casting operations in foundries and metal processing plants

Product Type : Other, Casting Platform

Technology : Other, Welding and Fabrication

Color : Grey

Drive Type : Electric Drive

Continuous Casting Machine Pusher Assembly

Minimum Order Quantity : depends Unit

Usage & Applications : Continuous Casting Machinery in Steel and Metal Industries

Product Type : Other, Continuous Casting Machine Pusher Assembly

Technology : Other, Advanced Fabrication and Machining

Color : Metallic Grey / Customized

Drive Type : Mechanical/Hydraulic/Electric

Ladle Bell Arm

Minimum Order Quantity : depends Unit

Usage & Applications : Used in handling and supporting ladles in foundries and steel plants

Product Type : Other, Ladle Bell Arm

Technology : Other, Precision Engineering

Color : Industrial Grey

Drive Type : Manual/Mechanical