Ladle Bell Arm

Ladle Bell Arm Specification

- Diameter

- Custom as per design

- Features

- High Strength, Wear Resistance, Precision Machined

- Size

- Standard and Custom Sizes Available

- Noise Level

- Minimal

- Capacity

- Up to 100 tons

- Lubricating System

- Grease Lubrication Provided

- Usage & Applications

- Used in handling and supporting ladles in foundries and steel plants

- Drive Type

- Manual/Mechanical

- Surface Finish

- Corrosion Resistant Finish

- Shape

- Curved Arm

- Product Type

- Ladle Bell Arm

- Material

- Forged Steel

- Technology

- Precision Engineering

- Power Source

- Mechanical

- Power

- Manual/Mechanical

- Surface Treatment

- Heat Treated and Painted

- Dimension (L*W*H)

- Custom as per application

- Color

- Industrial Grey

Ladle Bell Arm Trade Information

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- corrugated /wooden boxes

- Main Export Market(s)

- North America, Eastern Europe, Western Europe, Central America, Australia, Middle East, South America, Asia, Africa

- Main Domestic Market

- All India

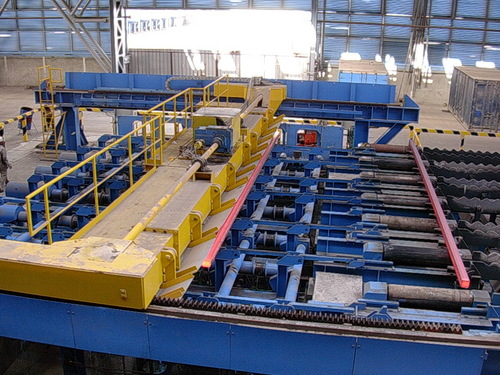

About Ladle Bell Arm

Catering to the needs of mechanical industry, we are engaged in manufacturing, supplying and export Ladle Bell Arm. Based on innovative technology, these are made at our technically upgraded manufacturing units with the help of latest machinery. In order to obtain the end product as per the expectations of clients, these are checked at different steps of manufacturing process by our team of quality analyzers. Owing to our wide network of delivery system, we supply the Ladle Bell Arm within the promised time frame at clients premises.

Features:

- Easy to install

- Robust design

- Low Maintenance

- Power efficient

Precision Construction for Demanding Applications

The Ladle Bell Arm stands out due to its meticulous construction using forged steel and precision machining. This ensures exceptional strength and wear resistance, making it ideal for the rigorous demands of foundries and steel plants. The heat-treated, painted finish enhances durability, providing effective protection against corrosion and increasing lifespan.

Versatile Design to Fit Every Requirement

Offered in both standard and customized sizes, the Ladle Bell Arm accommodates a wide array of applications. The custom dimension and diameter options allow it to align seamlessly with diverse ladle handling systems. This flexibility ensures compatibility and efficient operation in various industrial settings.

Smooth Operation and Low Maintenance

Fitted with a grease lubrication system, the Ladle Bell Arm guarantees reduced friction and noise during manual or mechanical use. Its minimal maintenance requirements, coupled with a corrosion-resistant surface finish, make it a reliable choice for continuous operation in intense industrial environments.

FAQs of Ladle Bell Arm:

Q: How does the Ladle Bell Arm improve ladle handling in foundries and steel plants?

A: The Ladle Bell Arm enhances ladle handling by providing robust mechanical support, ensuring safe and steady movement of ladles during pouring operations. Its precision engineering and high-strength forged steel construction reduce operational risk and improve efficiency in material handling.Q: What is the benefit of the corrosion-resistant finish on the Ladle Bell Arm?

A: The corrosion-resistant finish, achieved through heat treatment and painting, protects the arm from rust and degradation in harsh industrial environments. This extends the products service life and maintains reliability under demanding conditions.Q: Where can the Ladle Bell Arm be used?

A: The Ladle Bell Arm is designed for use in foundries and steel plants where heavy ladle handling and support are required. Its versatility makes it suitable for integration into various ladle handling systems.Q: What sizes and dimensions are available for the Ladle Bell Arm?

A: The Ladle Bell Arm is available in standard sizes as well as custom lengths, widths, heights, and diameters tailored to specific application needs, ensuring compatibility with most industrial setups.Q: How is the surface of the Ladle Bell Arm treated for durability?

A: The arm undergoes heat treatment followed by painting to achieve a durable, corrosion-resistant surface. This treatment minimizes wear and increases resistance to environmental factors that can cause damage over time.Q: What type of lubrication system is included and how does it benefit operation?

A: A grease lubrication system is provided with the Ladle Bell Arm. This system minimizes friction and ensures smooth manual or mechanical operation, reducing maintenance needs and extending component lifespan.

- Minimum Order Quantity

- depends Unit

- Main Domestic Market

- All India

- Main Export Market(s)

- North America, Eastern Europe, Western Europe, Central America, Australia, Middle East, South America, Asia, Africa

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Casting Machine Spare Parts Category

Rigid Dummy Bar Storage

Minimum Order Quantity : depends Unit

Usage & Applications : Continuous Casting Machines in Steel Plants

Technology : Other, Precision Engineering

Color : Industrial Grey

Product Type : Other, Rigid Dummy Bar Storage

Surface Treatment : Other, Heat Treated & Painted

Mould Oscillation Assembly

Minimum Order Quantity : depends Unit

Usage & Applications : Continuous Casting Machines in Steel Plants

Technology : Other, Precision Machining

Color : Silver/Grey

Product Type : Other, Mould Oscillation Assembly

Surface Treatment : Other, Polished and Coated

Mould Cooling System

Minimum Order Quantity : Depends Unit

Usage & Applications : Plastic Mould Cooling, Injection Molding Machines

Technology : Other, Advanced Heat Exchange

Color : Silver Grey

Product Type : Other, Mould Cooling System

Surface Treatment : Other, Powder Coated

Continuous Casting Machine Pusher Assembly

Minimum Order Quantity : depends Unit

Usage & Applications : Continuous Casting Machinery in Steel and Metal Industries

Technology : Other, Advanced Fabrication and Machining

Color : Metallic Grey / Customized

Product Type : Other, Continuous Casting Machine Pusher Assembly