Rigid Dummy Bar Storage

Rigid Dummy Bar Storage Specification

- Noise Level

- <75 dB

- Shape

- Rectangular

- Size

- Custom/Standard

- Motor Power

- 5 HP

- Usage & Applications

- Continuous Casting Machines in Steel Plants

- Lubricating System

- Centralized Automatic Lubrication

- Capacity

- Up to 10 Dummy Bars

- Drive Type

- Electric Motor

- Features

- Corrosion resistant, heavy load bearing, easy bar retrieval

- Surface Finish

- Smooth

- Product Type

- Rigid Dummy Bar Storage

- Material

- High Grade Steel

- Technology

- Precision Engineering

- Power Source

- Electric

- Power

- 5 kW

- Voltage

- 415 V

- Pressure

- Standard Atmospheric

- Surface Treatment

- Heat Treated & Painted

- Dimension (L*W*H)

- 3000 mm x 1500 mm x 2500 mm

- Weight

- 1800 kg

- Color

- Industrial Grey

Rigid Dummy Bar Storage Trade Information

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Corrugated /wooden boxes

- Main Export Market(s)

- Eastern Europe, Africa, Western Europe, Central America, Middle East, South America, Asia, North America, Australia

- Main Domestic Market

- All India

About Rigid Dummy Bar Storage

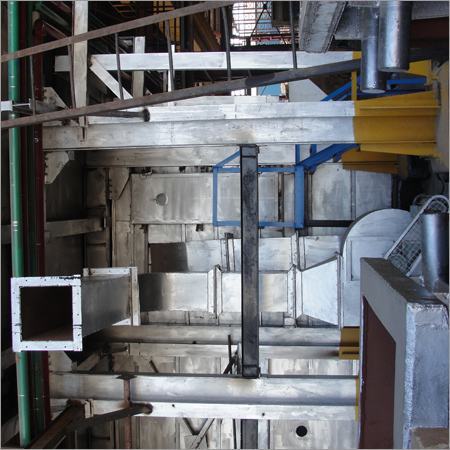

Encouraged by the support of large customer base across the nation, we are actively involved in manufacturing, supplying and exporting Rigid Dummy Bar Storage. The offered product is used in continuous casting machine during the process of casting. The entire range is manufactured under the guidance of high ranking officials who hold immense expertise in the same. Offered in varied technical specifications, the Rigid Dummy Bar Storage can be availed by clients as per their specific requirements.

Features:

- Resistant to corrosion

- High tensile strength

- Easy to maintain

- Robust design

Other Details:

Rigid Dummy Bar Storage

| Function | Storing and insertion of the rigid dummy bar into the withdrawal and straightening unit |

| Location | On support structure above intermediate roller table |

| Construction | Driving, guiding and storing system for rigid dummy bar, perfect guiding and safe storing of the rigid dummy bar |

Precision Construction for Industrial Demands

Manufactured from premium high-grade steel and engineered for tight tolerances, this storage unit excels in high-volume steel production environments. The heat treatment and painted finish protect against wear, corrosion, and harsh industry conditions, ensuring longevity and maximum load-bearing performance. The sturdy rectangular design is tailored for efficient operation and space optimization within steel plants.

User-Friendly Features and Advanced Technology

This dummy bar storage incorporates a centralized automatic lubrication system, significantly reducing routine maintenance while promoting optimal operational efficiency. The electric drive motor and smooth retrieval mechanism enable quick, safe, and easy bar access. Equipped to handle up to 10 dummy bars, it supports both standard and custom requirements for steel casting machinery.

FAQs of Rigid Dummy Bar Storage:

Q: How does the Rigid Dummy Bar Storage improve bar handling in steel plants?

A: The storage system is designed to facilitate swift and effortless retrieval and placement of dummy bars, essential for uninterrupted operation of continuous casting machines. Its robust construction and smooth surface finish minimize potential damage to bars, ensuring consistent handling.Q: What materials and treatments are used to ensure durability?

A: This unit is built from high-grade steel and further enhanced with heat treatment and industrial paint. These processes provide resistance against corrosion, heavy loads, and environmental wear, extending the lifespan of the storage system.Q: When should the dummy bars be stored in this system?

A: Dummy bars should be stored after each casting operation and during scheduled maintenance to maintain their condition and readiness, keeping the workspace organized and safe within steel production lines.Q: Where is the Rigid Dummy Bar Storage typically installed?

A: It is typically positioned adjacent to or within the casting area of large steel plants, maximizing accessibility for quick deployment and storage of dummy bars in continuous casting machine operations.Q: What is the recommended process for using this storage system?

A: Operators can use the easy bar retrieval mechanism to securely deposit or collect dummy bars. Maintenance needs are minimized thanks to the centralized automatic lubrication, and operation is both safe and quiet with noise levels below 75 dB.Q: What are the key benefits for steel plant operations?

A: The systems heavy load capacity, corrosion resistance, and simplified bar handling improve workplace efficiency, reduce downtime, and extend the life of dummy bars, offering a reliable asset for steel production facilities.

- Minimum Order Quantity

- depends Unit

- Main Domestic Market

- All India

- Main Export Market(s)

- Eastern Europe, Africa, Western Europe, Central America, Middle East, South America, Asia, North America, Australia

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Casting Machine Spare Parts Category

Casting Platform

Minimum Order Quantity : depends Unit

Size : As per required

Technology : Other, Welding and Fabrication

Dimension (L*W*H) : Customized

Noise Level : Low

Shape : Rectangular

Duct Steam Exhauster

Minimum Order Quantity : depends

Size : Standard

Technology : Other, Centrifugal Exhaust

Dimension (L*W*H) : 650 x 435 x 850 mm

Noise Level : <70 dB

Shape : Rectangular Duct Design

Ladle Bell Arm

Minimum Order Quantity : depends Unit

Size : Standard and Custom Sizes Available

Technology : Other, Precision Engineering

Dimension (L*W*H) : Custom as per application

Noise Level : Minimal

Shape : Curved Arm

Straightening Assembly

Minimum Order Quantity : depends Unit

Size : Customizable

Technology : Other, Mechanical Straightening

Dimension (L*W*H) : Approx. 2000 x 600 x 1200 mm

Noise Level : < 75 dB

Shape : Rectangular Frame