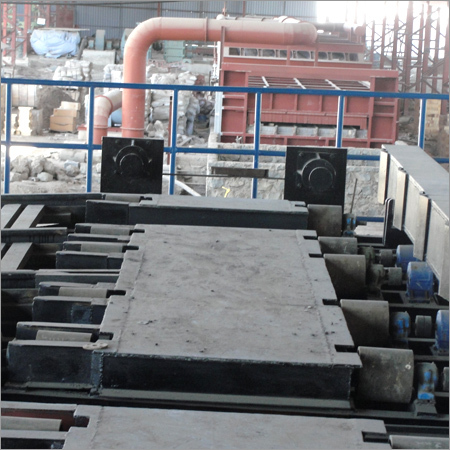

Straightening Assembly

Straightening Assembly Specification

- Shape

- Rectangular Frame

- Motor Power

- 3 HP (Standard)

- Noise Level

- < 75 dB

- Size

- Customizable

- Drive Type

- Gear Driven

- Usage & Applications

- Wire, tube, or rod straightening in industrial facilities

- Lubricating System

- Automatic or Manual Choice

- Surface Finish

- Smooth Coated

- Product Type

- Straightening Assembly

- Material

- Mild Steel (MS)

- Technology

- Mechanical Straightening

- Power Source

- Electric

- Pressure

- Ambient

- Surface Treatment

- Paint Coated

- Dimension (L*W*H)

- Approx. 2000 x 600 x 1200 mm

- Color

- Dark Grey/Blue

Straightening Assembly Trade Information

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- corrugated /wooden boxes

- Main Export Market(s)

- Eastern Europe, Africa, Central America, Australia, Middle East, South America, Western Europe, Asia, North America

- Main Domestic Market

- All India

About Straightening Assembly

With the support of technically profound engineers, we are able to manufacture, supply and export Straightening Assembly. The offered assembly is used in the continuous casting process for withdrawing and straightening of the cast strand. Each part of the assembly is made with great precision so as to ensure its easy fitting and longer life. To ensure compliance of our products with the international quality standards, we duly check these on several predefined parameters. Straightening Assembly is made available in different technical specifications that can be availed by clients as per their needs.

Attributes:

- Easy to install

- Dimensional stability

- Resistant to corrosion

- Precisely engineered

Additional information:

| Function | The withdrawal and straightening unit consists of two sections. The first is the withdrawal part, closest to the cooling chamber and the second is straightener part, prior to the intermediate roller table. The function is to withdraw and straighten the cast strand, as well as for insertion of the dummy bar for initiation/ re-stranding of the cast. |

| Location | After cooling chamber, on tangent point of casting radius. |

| Construction | rocker arm withdrawal and straightening unit with hydraulically loaded top rollers and three frequency-controlled AC drives, mounted on the rollers through Gear units |

| Type of drive | Frequency controlled AC-motors via gearboxes |

| Type of actuation of rocker arms | Hydraulically actuated cylinders, pressure adjustment by means of proportional pressure reducing valves. Independent adjustable on each rocker arm |

| Unbending | Fidus Achates Continuous Straightening - |

| Roller pressure | Applied by hydraulic cylinders |

- Sturdy design for heavy duty.

- Low unbending stress due to continuous unbending system and five-roller design.

- Use of standardized AC-motors with high availability and practically free of maintenance.

- AC-drives located outside critical heat radiation.

- Hydraulically actuated rocker arms for jerk-free withdrawal of strand.

- Cooling panels protect the equipment against heat radiation generated by the hot strand

Advanced Mechanical Straightening for Industrial Applications

Engineered for the rigorous demands of industrial facilities, this straightening assembly delivers precise correction for wires, tubes, or rods. Its robust Mild Steel (MS) construction and paint coating provides longevity and corrosion resistance, while the gear-driven 3 HP motor ensures uniform results with each operation. Its adaptable design allows for a variety of customizable sizes, fitting seamlessly into different production lines.

Optimized Performance with User-Friendly Features

From its automatic or manual lubrication options to a quiet operation under 75 dB, the assembly emphasizes operator safety and minimal maintenance. The smooth coated surface finish enhances material output quality, and the rectangular frame offers structural stability. Dealers, distributors, exporters, importers, and other industry professionals in India can rely on this assembly for seamless integration and consistent output.

FAQs of Straightening Assembly:

Q: How does the mechanical straightening process in this assembly work?

A: The mechanical straightening process utilizes gear-driven technology and a 3 HP electric motor to adjust and align wires, tubes, or rods as they pass through the assembly. Rollers and guides apply even pressure, straightening materials efficiently at ambient pressure without compromising their integrity.Q: What materials and dimensions can be handled with this straightening assembly?

A: This equipment is crafted from Mild Steel (MS) and is primarily used for wire, tube, or rod straightening. Standard dimensions are approximately 2000 x 600 x 1200 mm, but the size can be customized to match specific production requirements. The robust frame and smooth finish also support the handling of various material sizes.Q: When should the lubricating system be used, and what options are available?

A: The lubricating system should be used regularly to maintain optimal performance and extend the assemblys service life. Operators can choose between automatic or manual lubrication, depending on their maintenance preferences and operational schedules.Q: Where can this straightening assembly be installed and applied?

A: The assembly is ideal for industrial facilities such as manufacturing plants, workshops, or processing centers focusing on wire, tube, or rod products. It integrates well in production environments where precise straightening and reliability are essential.Q: What are the main usage scenarios and benefits of this straightening assembly?

A: It is used mainly for straightening wires, tubes, or rods before further processing or assembly. Major benefits include increased material uniformity, reduced production waste, and enhanced operational efficiencyall achieved with a noise level below 75 dB and a smooth, durable finish.Q: How does the coating and surface finish contribute to the assemblys durability?

A: A paint-coated surface and smooth finish provide protection against corrosion, wear, and environmental factors. This ensures the component remains reliable, reducing downtime and maintenance costs over prolonged industrial use.

- Minimum Order Quantity

- depends Unit

- Main Domestic Market

- All India

- Main Export Market(s)

- Eastern Europe, Africa, Central America, Australia, Middle East, South America, Western Europe, Asia, North America

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Casting Machine Spare Parts Category

Mould Oscillation Assembly

Minimum Order Quantity : depends Unit

Technology : Other, Precision Machining

Color : Silver/Grey

Product Type : Other, Mould Oscillation Assembly

Usage & Applications : Continuous Casting Machines in Steel Plants

Noise Level : 75 dB

Rigid Dummy Bar Storage

Minimum Order Quantity : depends Unit

Technology : Other, Precision Engineering

Color : Industrial Grey

Product Type : Other, Rigid Dummy Bar Storage

Usage & Applications : Continuous Casting Machines in Steel Plants

Noise Level : <75 dB

Billet Stopper

Minimum Order Quantity : depends Unit

Technology : Other, Forged and Machined

Color : Industrial Grey or Custom

Product Type : Other, Billet Stopper

Usage & Applications : Steel Plants, Continuous Casting Machines, Billet Handling Operations

Noise Level : Low

Discharge Roller Table

Minimum Order Quantity : depends

Technology : Other, Hot Rolled

Color : Industrial Grey / Blue / Customized

Product Type : Other, Discharge Roller Table

Usage & Applications : Rolling Mills, Steel Plants, Metal Processing Units, Conveyor Lines

Noise Level : Below 70 dB