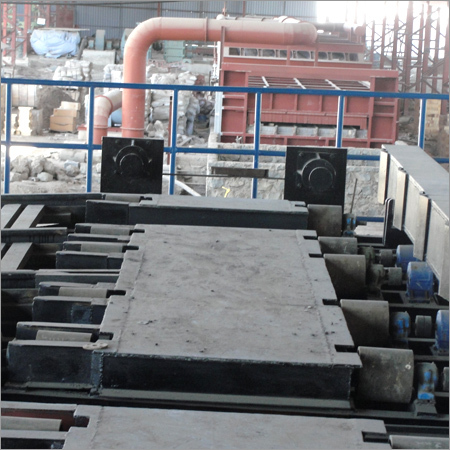

Billet Stopper

Billet Stopper Specification

- Size

- Varies as per design

- Lubricating System

- Automatic/Manual Grease Fittings

- Drive Type

- Hydraulic Drive

- Shape

- Rectangular/Custom

- Surface Finish

- Smooth, Corrosion Resistant

- Usage & Applications

- Steel Plants, Continuous Casting Machines, Billet Handling Operations

- Motor Power

- As per design requirement

- Features

- High Durability, Heavy Load Bearing, Precision Engineered

- Capacity

- Suitable for medium to heavy billets

- Noise Level

- Low

- Product Type

- Billet Stopper

- Material

- Alloy Steel

- Technology

- Forged and Machined

- Power Source

- Hydraulic

- Power

- Customizable as per application

- Pressure

- High Pressure Hydraulic System

- Surface Treatment

- Heat Treated and Painted

- Dimension (L*W*H)

- Custom Built (as per specification)

- Weight

- Depending on size and requirement

- Color

- Industrial Grey or Custom

Billet Stopper Trade Information

- Payment Terms

- Cheque, Telegraphic Transfer (T/T), Cash in Advance (CID), Cash Advance (CA)

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- corrugated /wooden boxes

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Africa, Western Europe, Central America, South America, Asia

- Main Domestic Market

- All India

About Billet Stopper

Starting from our commencement in 2007, we are actively indulged in manufacturing, supplying and exporting Billet Stopper. The offered product is used in continuous casting machines to monitor and stops the billet along with offering support to heavy profiles. Our team of experienced professions make sure that all products are made in compliance with the international quality standards by strictly monitoring the entire manufacturing process. In order to prove the trust of our clients, we supply bulk quantities of quality tested Billet Stopper to clients as per their requirements in a time bound manner.

Features:

- Resistant to corrosion

- High speed performance

- Easy to install

- High tensile strength

FAQs

Q: What is a billet stopper?

A: A billet stopper is a type of metal pin that is inserted into the end of a metal bar to prevent it from splitting. It is also known as a bar end plug or a bar end pin.

Q: How is a billet stopper used?

A: Billet stoppers are typically used to secure metal bars in place, such as in the construction of furniture or other structures. They are also used in the automotive industry to secure suspension components or exhaust systems.

Q: What materials are billet stoppers made from?

A: Billet stoppers are usually made from metal, such as aluminum or stainless steel. The material will depend on the application and the strength requirements of the bar or structure.

Engineered for Heavy-Duty Operations

Designed for medium to heavy billet management, this hydraulic Billet Stopper features a forged and machined alloy steel body, delivering remarkable strength. Its precision engineering allows seamless operation in high-load environments like steel plants, with custom sizing and coloration to suit any application.

Customizable Power and Dimensions

Every Billet Stopper is built to your specifications, including length, width, height, and hydraulic power. This ensures a tailored fit within your continuous casting lines or billet handling setup, maximizing efficiency and adaptability for various manufacturing processes.

Superior Surface Protection and Durability

A heat-treated, painted finish ensures excellent corrosion resistance, while a smooth surface finish maintains equipment integrity and appearance. Whether in industrial grey or a custom color, the stopper withstands harsh operational environments with minimal maintenance.

FAQs of Billet Stopper:

Q: How is the Billet Stopper powered and what are its customization options?

A: The Billet Stopper is powered by a high-pressure hydraulic system, with power levels fully customizable according to your application requirements. Dimensions, weight, and color can also be tailored to fit specific operational needs.Q: What materials and technologies are used in manufacturing the Billet Stopper?

A: It is constructed from forged and machined alloy steel, providing superior strength and longevity. Advanced forging and machining techniques ensure precision and high durability under heavy loads.Q: When should I consider using a Billet Stopper in my facility?

A: Billet Stoppers are recommended for use when handling medium to heavy billets, especially in steel plants and continuous casting machines, where precise control and high load-bearing capacities are required.Q: Where can the Billet Stopper be utilized?

A: This equipment is primarily used in billet handling operations, steel manufacturing plants, and continuous casting lines. Its adaptable design allows integration into both new and existing industrial setups.Q: What is the process for installing and maintaining the Billet Stopper?

A: Installation involves aligning the custom-built unit to your system specifications, connecting the hydraulic drive, and setting up either the automatic or manual grease fittings for lubrication. Regular maintenance is minimal thanks to its robust build and corrosion-resistant surface.Q: How does the Billet Stopper improve operational efficiency?

A: Its precision engineering, high load resistance, and reliable hydraulic operation result in smoother billet handling, reduced downtime, and increased safety during material transfer operations.Q: What are the key benefits of choosing this Billet Stopper?

A: Key advantages include longevity, heavy-duty performance, minimal noise, flexible customization, and excellent corrosion resistancemaking it a dependable choice for dealers, manufacturers, suppliers, and service providers in industrial sectors across India.

- Minimum Order Quantity

- depends Unit

- Main Domestic Market

- All India

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Africa, Western Europe, Central America, South America, Asia

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Casting Machine Spare Parts Category

Rigid Dummy Bar Storage

Minimum Order Quantity : depends Unit

Surface Treatment : Other, Heat Treated & Painted

Color : Industrial Grey

Technology : Other, Precision Engineering

Usage & Applications : Continuous Casting Machines in Steel Plants

Product Type : Other, Rigid Dummy Bar Storage

Mould Cooling System

Minimum Order Quantity : Depends Unit

Surface Treatment : Other, Powder Coated

Color : Silver Grey

Technology : Other, Advanced Heat Exchange

Usage & Applications : Plastic Mould Cooling, Injection Molding Machines

Product Type : Other, Mould Cooling System

Straightening Assembly

Minimum Order Quantity : depends Unit

Surface Treatment : Other, Paint Coated

Color : Dark Grey/Blue

Technology : Other, Mechanical Straightening

Usage & Applications : Wire, tube, or rod straightening in industrial facilities

Product Type : Other, Straightening Assembly

Continuous Casting Machine Tundish

Minimum Order Quantity : depends Unit

Surface Treatment : Other, Paint coated, Sand blasted

Color : Industrial Grey or as per requirement

Technology : Other, Continuous Casting Technology

Usage & Applications : Molten metal distribution in continuous casting process

Product Type : Other, Continuous Casting Machine Tundish