Emergency Launder

Emergency Launder Specification

- Drive Type

- Push/Pull Rod, Foot Pedal, Paddle Operated

- Size

- Standard

- Surface Finish

- Bright/Glossy/Smooth

- Lubricating System

- Not Required

- Noise Level

- Silent Operation

- Shape

- Vertical With Circular Bowl (Eye Wash)

- Usage & Applications

- For chemical plants, laboratories, factories, warehouses, and hazardous locations

- Product Type

- Emergency Shower and Eye Wash (Launder)

- Material

- Stainless Steel (Grade 304/316)

- Technology

- Gravity/Direct Piping System

- Power Source

- Manual/Water Pressure Driven

- Pressure

- 2.0 to 6.0 kg/cm2 (Recommended Working Pressure)

- Surface Treatment

- Polished, Corrosion Resistant Finish

- Dimension (L*W*H)

- Approx. 750 x 300 x 2200 mm

Emergency Launder Trade Information

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- corrugated /wooden boxes

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Africa, Western Europe, Central America, South America, Asia

- Main Domestic Market

- All India

About Emergency Launder

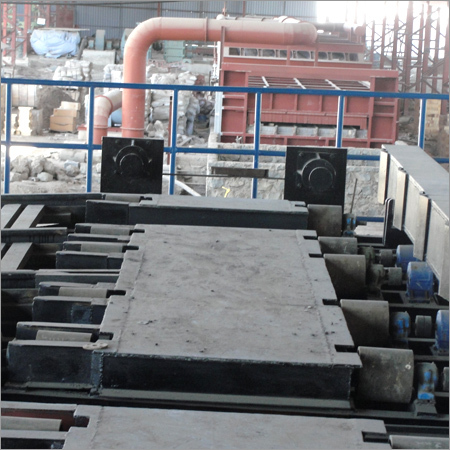

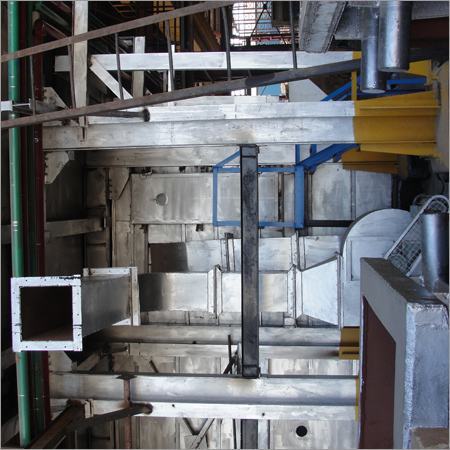

With a vision to attain the highest position in this domain, we are persistently involved in manufacturing and supplying Emergency Launder. Designed as per the different industrial needs, these are ideally used in the manufacturing process of casts by open casting technique. Assisted by profound procurement agents, we are able to source fine grade steel and other material required for making the aforesaid product. Offered by us, the Emergency Launder is high in demand among clients for the following features:

-

Resistant to corrosion

-

Accurate dimensions

-

High tensile strength

-

Dimensional stability

Additional information:

Function

It can be swung under the tundish nozzle as required, e.g. at start resp. at end of cast or in case of emergency

Location

-

The emergency launder is attached to the tundish car by a pivot on the crossbeam opposite the mould operator station.

-

Emergency launders are only used for open casting technique.

-

Lubrication a hand grease gun is used to service the bearing grease nipples.

Superior Safety Solution for Industrial Environments

Engineered for high-risk industrial and laboratory settings, this emergency launder provides immediate, effective first aid for chemical exposures. Its robust stainless steel build withstands corrosive substances while polished finishing ensures minimal maintenance. With multiple activation methodsincluding push/pull, foot pedal, and paddleit caters to diverse workplace needs, enhancing both compliance and safety for personnel dealing with hazardous materials.

Versatile Installation and Hassle-Free Maintenance

The units vertical structure with a compact footprint allows installation in limited spaces without compromising efficiency. Its direct piping or gravity-fed system supports varied water supply configurations, making it adaptable to different site requirements. The bright, smooth surface rarely accumulates deposits, and the lack of lubrication needs ensures hassle-free maintenance and sustained performance, reducing overall operational downtime.

FAQs of Emergency Launder:

Q: How is the emergency launder activated in case of an incident?

A: The emergency launder is activated using a push/pull rod, foot pedal, or paddle, allowing quick and hands-free operation even in stressful situations. This design ensures immediate access to water flow for rapid washing or eye rinsing.Q: What types of environments is this emergency launder best suited for?

A: It is ideal for use in chemical plants, laboratories, factories, warehouses, and other hazardous locations where chemical spills or exposure risks are present. The robust stainless steel construction ensures it performs well in corrosive and demanding settings.Q: When should the emergency launder be used?

A: This device should be used immediately after contact with hazardous chemicals or contaminants, particularly when there is risk of injury to the eyes or skin. Prompt use helps minimize potential harm and supports ongoing safety protocols.Q: Where can this emergency launder be installed?

A: Thanks to its vertical, space-efficient design and adaptable plumbing options, the emergency launder can be installed close to hazard-prone workstations or anywhere quick access to emergency washing is necessary in your facility.Q: What benefits does the corrosion-resistant stainless steel provide?

A: The use of Grade 304 or 316 stainless steel, combined with a polished, smooth surface, delivers exceptional durability and resistance to rust or corrosion. This ensures longevity and reliability, even under frequent use and harsh industrial conditions.Q: How does the gravity/direct piping system work?

A: The system either relies on gravity-fed water supply or connects directly to the main water line, operating efficiently within the recommended pressure range of 2.0 to 6.0 kg/cm. This setup ensures consistent and adequate water flow for emergency washing.

- Minimum Order Quantity

- depends Unit

- Main Domestic Market

- All India

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Africa, Western Europe, Central America, South America, Asia

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Casting Machine Spare Parts Category

Rigid Dummy Bar Storage

Minimum Order Quantity : depends Unit

Color : Industrial Grey

Surface Treatment : Other, Heat Treated & Painted

Product Type : Other, Rigid Dummy Bar Storage

Technology : Other, Precision Engineering

Usage & Applications : Continuous Casting Machines in Steel Plants

Billet Stopper

Minimum Order Quantity : depends Unit

Color : Industrial Grey or Custom

Surface Treatment : Other, Heat Treated and Painted

Product Type : Other, Billet Stopper

Technology : Other, Forged and Machined

Usage & Applications : Steel Plants, Continuous Casting Machines, Billet Handling Operations

Mould Cooling System

Minimum Order Quantity : Depends Unit

Color : Silver Grey

Surface Treatment : Other, Powder Coated

Product Type : Other, Mould Cooling System

Technology : Other, Advanced Heat Exchange

Usage & Applications : Plastic Mould Cooling, Injection Molding Machines

Duct Steam Exhauster

Minimum Order Quantity : depends

Color : Silver

Surface Treatment : Other, Powder Coated

Product Type : Other, Duct Steam Exhauster

Technology : Other, Centrifugal Exhaust

Usage & Applications : Commercial Kitchens, Food Processing Plants, Industrial Exhaust