Overhead Cross Transfer

Overhead Cross Transfer Specification

- Rating

- Heavy Duty

- Condition

- New

- Type

- Overhead Cross Transfer

- Usage

- Material Handling

- Power

- Electric

- Size

- Customizable as per requirement

- Dimensions

- Depends on Model (standard and customized available)

- Weight

- Varies as per design

- Application

- Industrial Automation, Conveyor Systems

- Fuel Type

- Electric

- Capacity

- Up to 2000 kg

- Control System

- PLC/Manual

- Conveyor Type

- Overhead Cross Transfer Conveyor

- Safety Features

- Emergency Stop, Overload Protection

- Color

- Industrial Standard (custom options available)

- Finish

- Powder Coated

- Material

- Mild Steel/SS

- Lifting Mechanism

- Chain Driven

- Noise Level

- Low

- Speed

- Adjustable as per application

Overhead Cross Transfer Trade Information

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Corrugated /Wooden boxes

- Main Export Market(s)

- Australia, North America, Eastern Europe, Africa, Central America, Middle East, South America, Western Europe, Asia

- Main Domestic Market

- All India

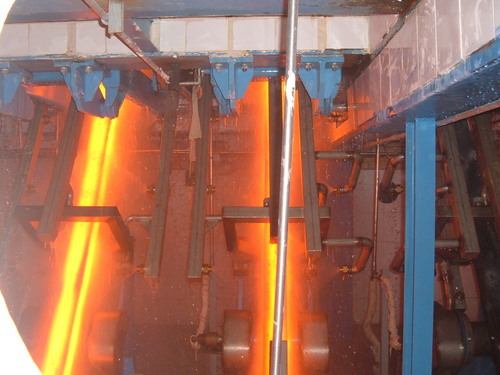

About Overhead Cross Transfer

With the support of our diligent manpower, we are able to manufacture, supply and export Overhead Cross Transfer. Incorporated with advanced technology, these machines are widely used for varied industrial applications. We make sure that all products are made using superior quality stainless steel under the surveillance of high ranking officials so as to rule our any manufacturing defect. We offer the Overhead Cross Transfer in varied specifications in order to cater to the exact demands of clients.

Features:

- Easy to install

- Low maintenance

- User-friendly

- Longer service life

FAQs

1. What is an Overhead Cross Transfer?

An Overhead Cross Transfer (OCT) is a method of transferring weight from one arm to the other in a standing position. It is commonly used in bodyweight training to increase core stability and coordination.

2. What muscles does an Overhead Cross Transfer work?

An Overhead Cross Transfer works several muscles, including the core, glutes, and upper body. Specifically, it works the lats, traps, rhomboids, and deltoids in the upper body and the obliques, quads, hamstrings, and calves in the lower body.

3. How do I perform an Overhead Cross Transfer?

To perform an Overhead Cross Transfer, stand with your feet shoulder-width apart, your arms extended overhead, and your palms facing each other. Keeping your core engaged, slowly transfer your weight from one arm to the other, creating a circular motion with your arms. Make sure to keep your back straight and move in a controlled manner.

Tailored for Industrial Automation

This overhead cross transfer conveyor seamlessly integrates into modern industrial automation systems, offering flexibility with adjustable speeds and custom dimensions. Powered electrically and rated for heavy-duty use, it efficiently manages material flow while ensuring safety through advanced protection features for large-scale operations.

Safety and Efficiency Combined

Designed with operator safety in mind, the conveyor includes emergency stop controls and overload safeguards. Its low-noise performance and chain-driven lifting mechanism ensure smooth, reliable movement of goods, minimizing downtime and supporting continuous productivity in industrial settings.

Versatility and Customization

Available in standard industrial colors with custom options, the conveyors size, finish, and control system can be tailored to your specific application. Whether you are a manufacturer, trader, or wholesaler, this system accommodates varied material handling needs across diverse industries.

FAQs of Overhead Cross Transfer:

Q: How does the Overhead Cross Transfer Conveyor enhance material handling processes?

A: The conveyor streamlines material movement over production areas by carrying loads overhead, reducing floor congestion and enhancing workflow efficiency. Its adjustable speed and chain-driven lifting allow for smooth transfer of heavy loads up to 2000 kg, making it ideal for demanding automation setups.Q: What are the key safety features of this conveyor system?

A: It is equipped with an emergency stop function and overload protection. These features provide rapid response to operational hazards and help prevent equipment damage or workplace injuries, ensuring safer working conditions in industrial applications.Q: When should I consider choosing a PLC control system over manual controls?

A: A PLC control system is recommended for automated or complex workflows requiring precise operation and integration with other equipment. Manual controls are ideal for simpler setups or where hands-on adjustments are needed. The choice depends on your applications automation level and operational complexity.Q: Where can this conveyor be installed?

A: It can be installed in various industrial environmentsfactories, warehouses, or any facility involved in material handling and automation. The conveyors customizable size and configuration make it adaptable to both existing and newly planned infrastructures.Q: What process is followed for customizing the conveyor size and design?

A: Customization begins with assessing the clients material handling requirements, followed by designing the conveyor specifications such as dimensions, capacity, color, and finish. The system is then manufactured to the agreed specifications and installed by qualified technicians, ensuring optimal fit and performance.Q: How is the Overhead Cross Transfer Conveyor beneficial compared to traditional floor conveyors?

A: Overhead cross transfer conveyors maximize available workspace by utilizing overhead space, improve safety by keeping materials above ground level, and can navigate over obstacles. They offer better space management and increased throughput in busy industrial settings.Q: What maintenance is required to ensure optimal conveyor performance?

A: Regular inspection of the chain-driven mechanism, timely lubrication, monitoring of control systems, and checking safety devices are essential. Scheduled maintenance helps in extending the equipments lifespan and reducing unplanned downtime.

- Minimum Order Quantity

- depends Unit

- Main Domestic Market

- All India

- Main Export Market(s)

- Australia, North America, Eastern Europe, Africa, Central America, Middle East, South America, Western Europe, Asia

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Continuous Casting Machine Category

Tundish Preheater

Minimum Order Quantity : depends Unit

Dimensions : As per customer/plant requirement

Size : Customized as per Tundish capacity

Rating : Up to 2000 kW

Condition : New

Type : Industrial Preheater

Cast Spray Pipes

Minimum Order Quantity : Depends on Product Ton

Dimensions : Varies as per size selection

Size : 3/4 inch to 6 inch (custom sizes available)

Rating : High performance, manufacturer quality approved

Condition : New

Type : Spray Pipe

Ladle Turret

Minimum Order Quantity : depends Unit

Dimensions : As per project design

Size : Customizable as per requirement

Rating : Heavy Duty

Condition : New

Type : Industrial

Industrial Torch Cutting Machine

Minimum Order Quantity : depends Unit

Dimensions : Approximately 1200 mm x 800 mm x 950 mm

Size : Standard (custom options available)

Rating : Industrial Grade

Condition : New

Type : Manual/Automatic Torch Cutting Machine