Rigid Dummy Bar

Rigid Dummy Bar Specification

- Diameter

- As per specification

- Capacity

- High Load Bearing

- Surface Finish

- Smooth

- Size

- Customized

- Drive Type

- Mechanical

- Noise Level

- Low

- Usage & Applications

- Continuous Casting in Steel Plants

- Shape

- Round/Rod

- Product Type

- Rigid Dummy Bar

- Material

- Alloy Steel

- Technology

- Centrifugal Casting

- Power Source

- Mechanical

- Surface Treatment

- Galvanized / Polished

- Dimension (L*W*H)

- Customized as per requirement

- Weight

- Varies as per size

- Color

- Metallic Silver / Grey

Rigid Dummy Bar Trade Information

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- corrugated /wooden boxes

- Main Export Market(s)

- Middle East, Africa, Western Europe, Australia, South America, Asia, Central America, Eastern Europe, North America

- Main Domestic Market

- All India

About Rigid Dummy Bar

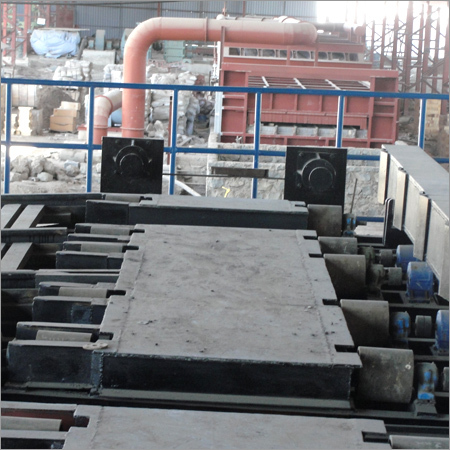

Rigid Dummy Bar

Rigid dummy bar is basically known for its commendable ability of sealing the bottom part of the mold when each and every casting begins, so that steel can easily be pored into it. With the special head shape, this bar is used to extract the partly solidified steel inside the mold til the bottom part in order to withdraw & straighten the unit. The product offered by the company is a radius of curvature that is equal to the casting radius. Also, the strength and rigidity of the Rigid dummy bar is appreciable.

| Function | At the start of a cast the rigid dummy bar head closes the mould. After start the driven bar leads the hot strand through the cooling chamber and withdrawal/ straightening unit. |

| Location | In dummy bar storage respectively inserted in mould |

| Construction | Rigid, curved type, made of several segments bolted with reamed bolts, front end machined to fit transition piece Rigid and sturdy construction of arc Segments can be individually exchanged in case of damage Short restranding time No obstacles exist (roller aprons, supports) in cooling chamber, therefore free access and perfect undisturbed spray pattern to hot strand Restranding during casting of individual strands is possible. |

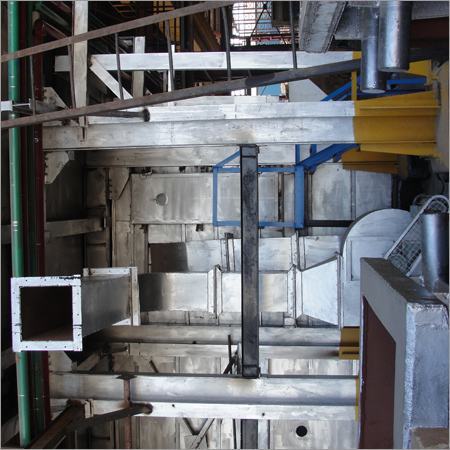

Precision Manufacturing for Enhanced Performance

Utilizing centrifugal casting, each Rigid Dummy Bar is produced with exceptional dimensional accuracy and structural integrity. The process ensures high mechanical strength, making it ideally suited for the rigorous demands of continuous casting in steel plants. Available in customizable sizes and diameters, these bars deliver reliable performance for diverse industrial applications.

Superior Material and Surface Treatments

Crafted from top-quality alloy steel, the dummy bars receive galvanized or polished finishes for improved corrosion resistance and smoother surface texture. This protection not only extends the products life but also enhances its operational efficiency under challenging industrial environments.

Seamless Integration and Customization

Every bar can be tailored in length, width, height, and shape based on customer specifications. This ensures perfect compatibility with a variety of steel plant operations. The seamless adaptability and mechanical drive system facilitate easy integration with existing manufacturing processes.

FAQs of Rigid Dummy Bar:

Q: How is the Rigid Dummy Bar utilized in continuous casting at steel plants?

A: It is inserted into the mold during continuous casting to support the initial metal flow. The mechanical drive facilitates movement, guiding the steel through the process and ensuring uniform formation of slabs or billets.Q: What materials and surface treatments are used in the construction of the dummy bar?

A: The dummy bar is made from high-strength alloy steel, finished with either galvanization or polishing to provide excellent corrosion resistance and a smooth surface for optimal casting performance.Q: When should a customized dummy bar be chosen for industrial applications?

A: A customized dummy bar is recommended when specific dimensions, diameters, or load capacities are required to match unique casting equipment or specialized production needs in steel plants.Q: Where can organizations in India source these Rigid Dummy Bars?

A: They are available for purchase from authorized dealers, distributors, manufacturers, exporters, importers, suppliers, service providers, traders, and wholesalers across India.Q: What is the production process behind these dummy bars?

A: The manufacturing involves centrifugal casting technology, which delivers uniform material properties and precise shapes, followed by finishing processes like galvanizing or polishing.Q: What are the main benefits of using this dummy bar in steel manufacturing?

A: Benefits include high load-bearing capacity, low operational noise, durable construction with corrosion-resistant finishes, and seamless integration into continuous casting lines.

- Minimum Order Quantity

- depends Unit

- Main Domestic Market

- All India

- Main Export Market(s)

- Middle East, Africa, Western Europe, Australia, South America, Asia, Central America, Eastern Europe, North America

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Casting Machine Spare Parts Category

Mould Oscillation Assembly

Minimum Order Quantity : depends Unit

Pressure : Hydraulic System Supported

Power Source : Other, Electric

Size : Customizable

Product Type : Other, Mould Oscillation Assembly

Dimension (L*W*H) : 1200 mm x 500 mm x 800 mm

Billet Stopper

Minimum Order Quantity : depends Unit

Pressure : High Pressure Hydraulic System

Power Source : Hydraulic

Size : Varies as per design

Product Type : Other, Billet Stopper

Dimension (L*W*H) : Custom Built (as per specification)

Duct Steam Exhauster

Minimum Order Quantity : depends

Pressure : Medium

Power Source : Other, Electric

Size : Standard

Product Type : Other, Duct Steam Exhauster

Dimension (L*W*H) : 650 x 435 x 850 mm

Casting Platform

Minimum Order Quantity : depends Unit

Pressure : Standard Atmospheric

Power Source : Other, Electric

Size : As per required

Product Type : Other, Casting Platform

Dimension (L*W*H) : Customized