Mould Oscillation Drive System

Mould Oscillation Drive System Specification

- Rating

- Heavy duty

- Condition

- New

- Type

- Electromechanical Oscillation Drive

- Usage

- Oscillation of continuous casting machine moulds

- Power

- 3 kW to 15 kW

- Size

- Customizable as per caster design

- Dimensions

- Varies as per model/capacity

- Application

- Steel Plant/Continuous Casting Machinery

- Fuel Type

- Electric

- Capacity

- Suitable for billets, blooms, and slabs

- Drive Mechanism

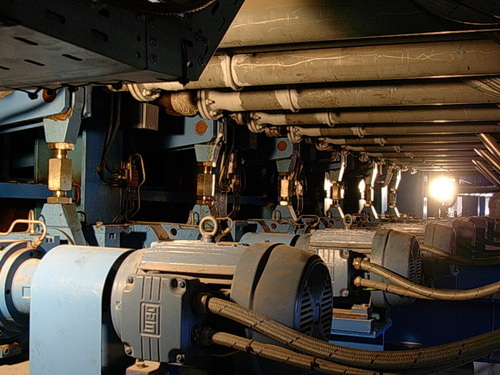

- Servo motor or geared motor

- Oscillation Frequency

- Up to 300 cycles/min (variable)

- Customization Options

- Stroke length, frequency, mounting, and interface on request

- Safety Features

- Overload protection, emergency stop switches

- Service Life

- Designed for 24/7 continuous operation

- Material

- Special alloy steel with surface hardening

- Noise Level

- <75 dB

- Lubrication

- Centralized automatic lubrication system

- Mounting

- Base plate mounting with vibration dampers

- Oscillation Stroke Length

- 2 mm to 30 mm (adjustable)

- Maintenance

- Easy access for inspection and servicing

Mould Oscillation Drive System Trade Information

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Corrugated /wooden boxes

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Middle East, Africa, Western Europe, Central America, Asia

- Main Domestic Market

- All India

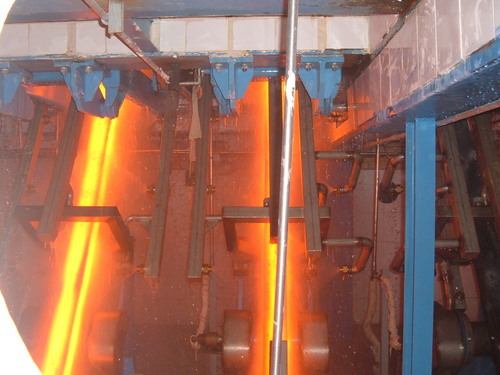

About Mould Oscillation Drive System

With our diligent efforts, we have attained a noteworthy position in the market as a manufacturer, supplier and exporter of Mould Oscillation Drive System. The entire manufacturing process is monitored by experienced professionals so as to obtain the end product as per the needs of modern industries. This system is used to provide required movement of the mold by minimizing the depth of oscillation waves. In order to cater to the variegated demands of clients, we offer the Mould Oscillation Drive System in different specifications.

Features:

- Optimum performance

- Non-abrasive

- Noise free performance

- High tensile strength

Optimized for Precision and Efficiency

This oscillation drive system combines advanced motors, precise control, and adjustable settings to ensure smooth mould oscillation, which is critical for the high-quality production of billets, blooms, and slabs. Its versatility supports a range of casting machinery applications in steel plants, allowing for tailored integration into different production environments.

Engineered for Endurance and Safety

Manufactured with hardened special alloy steel and equipped for continuous 24/7 operation, the system guarantees exceptional durability. Built-in features like centralized automatic lubrication, vibration dampers, overload protection, and emergency stop switches further bolster safety and reliability, reducing downtime and extending service life.

FAQs of Mould Oscillation Drive System:

Q: How is the oscillation stroke length and frequency adjusted in the Mould Oscillation Drive System?

A: The oscillation stroke length and frequency can be easily adjusted through the systems intuitive control unit, which allows operators to fine-tune stroke length from 2 mm to 30 mm and set frequencies up to 300 cycles per minute, ensuring precise mould motion for different casting requirements.Q: What are the primary benefits of using this oscillation drive system in steel plants?

A: The system enhances casting quality by delivering stable and accurate oscillation, reduces maintenance needs through automatic lubrication, operates quietly at less than 75 dB, and ensures uninterrupted production with 24/7 capability. Additionally, its robust safety features minimize operational risks.Q: When should regular maintenance or inspection be performed?

A: Routine inspections are recommended according to the manufacturers guidelines, typically every few months depending on operating conditions. The units design offers easy access for servicing, allowing for quick checking of lubrication, motor performance, and safety systems.Q: Where can this drive system be installed, and what are its mounting options?

A: This unit is built for steel plant environments and mounts via a base plate with integrated vibration dampers. Its design is flexible to accommodate various caster models, and it can be customized for different mounting and interface requirements upon request.Q: What is the process for customizing the drive system to suit specific casting machine requirements?

A: Customization is available for stroke length, oscillation frequency, mounting configuration, and system interface. Clients simply provide their application and design parameters, and the manufacturer will tailor the system accordingly to fit specific continuous casting setups.Q: How does the centralized automatic lubrication system work and what advantage does it provide?

A: The centralized automatic lubrication system continuously supplies lubrication to critical components, minimizing wear and maintenance intervals. This feature enhances system longevity, ensures consistent performance, and reduces manual intervention.Q: What types of moulds and casting products is the system suitable for?

A: It is engineered for versatile application with billet, bloom, and slab moulds used in continuous casting machinery, making it ideal for a range of capacities and steel products produced in modern steel plants.

- Minimum Order Quantity

- depends Unit

- Main Domestic Market

- All India

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Middle East, Africa, Western Europe, Central America, Asia

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Continuous Casting Machine Category

Tundish Preheater

Minimum Order Quantity : depends Unit

Size : Customized as per Tundish capacity

Condition : New

Type : Industrial Preheater

Dimensions : As per customer/plant requirement

Application : Continuous casting process

Cast Spray Pipes

Minimum Order Quantity : Depends on Product Ton

Size : 3/4 inch to 6 inch (custom sizes available)

Condition : New

Type : Spray Pipe

Dimensions : Varies as per size selection

Application : Cooling, water spray, dust control, and irrigation systems

Overhead Cross Transfer

Minimum Order Quantity : depends Unit

Size : Customizable as per requirement

Condition : New

Type : Overhead Cross Transfer

Dimensions : Depends on Model (standard and customized available)

Application : Industrial Automation, Conveyor Systems

Ladle Turret

Minimum Order Quantity : depends Unit

Size : Customizable as per requirement

Condition : New

Type : Industrial

Dimensions : As per project design

Application : Ladle handling in steelmaking operations